When it comes to choosing the suitable foam machine for your needs, it’s essential to take the time to research and understand the different types of machines available and their specific capabilities. There are a few crucial factors you’ll want to keep in mind whether you’re looking for continuous foam machines, batch foaming machines, or foam cutting machines.

Guide To Choose The Right Foam Machine

We have put up this buying guide for the best foam machine to suit your requirements to assist you in making an informed choice. We will help you with everything from comprehending the various machine types to considering variables like size and capacity.

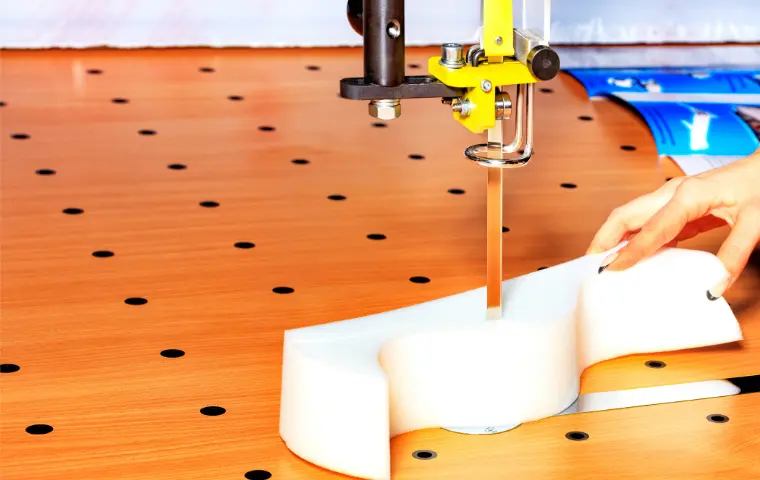

1. Types Of Foam Machines

Understanding the various machine types is crucial before looking for a foam machine. Foam machines can be divided into two categories: batch foaming machines and continuous foaming machines.

Continuous Foam Machines

Continuous foam machines are perfect for high-volume foam manufacturing since they are built to manufacture foam consistently. These devices are frequently employed in construction, automotive, and furniture production. The capacity of continuous foam machines to produce reliable, high-quality foam is one of its significant benefits. These machines are less prone to foam density and quality changes since they produce foam regularly. Therefore, they are perfect for industries that produce foam insulation or pillows, both of which require high levels of uniformity.

Batch Foaming Machines

However, batch foaming machine is made to create foam in smaller amounts. Industries, including foam insulation, rubber, and packaging, frequently use these devices. The adaptability of batch foaming machines is one of their key advantages. They can create foam in smaller volumes, making them perfect for various applications and industries. Additionally, batch foaming equipment is typically simpler to use and maintain, making it an excellent option for companies with little prior foam manufacturing experience.

2. Size and Capacity

It’s crucial to consider the machine’s size and capacity when selecting a foam machine. Your production facility’s size and the quantity of space you have for the device will determine the size of the machine. When choosing the capacity, think about the amount of foam you need to generate every day or every week. A machine with a bigger capacity is likely required if you are operating a large operation. Still, a smaller organization could get by with a smaller machine.

3. Foam Quality and Consistency

The caliber and consistency of the foam machine’s foam should be considered when deciding. Making foam for a given application requires making sure the foam complies with all essential requirements. Investing in a properly calibrated and maintained machine to guarantee consistent foam quality is crucial. The machine will operate at its peak performance level and generate high-quality foam with regular maintenance and calibration.

4. Ease of Use and Maintenance

The ease of operation and maintenance of foam machines should be considered. If you’re new to foam production, you should pick a machine that is simple to use and keep up with. Doing this can reduce the learning curve and ensure that your production can start without problems. On the other hand, if you are an expert in foam production and want a more sophisticated machine, think about a unit with various features and abilities. Selecting a machine that is nevertheless simple to use and maintain will help to keep your production operating smoothly.

5. Price and Budget

Price is, of course, a significant factor to consider when buying any machinery. Prices for foam machines can vary significantly based on the machine’s size, capacity, and features. It’s crucial to remember that you’ll want to invest in a machine that will satisfy your needs both now and in the future when determining your budget for a foam machine. While it may be tempting to go with the lowest alternative, this may not be the most economical decision. Instead, consider the advantages of purchasing a higher-quality machine in the long run.

6. Foam Machine Manufacturers

Once you’ve whittled down your choices based on size, capacity, foam quality, usability, and price, it’s time to start thinking about foaming machine manufacturers. There are numerous manufacturers, and each offers different products, like Santech Industries. A manufacturer’s reputation is one of the most important factors to consider. We are the leading producers with a proven track record of creating foam machines of the highest caliber. Additionally, it would be best if you thought about things like customer service, the availability of replacement parts, and the manufacturer’s entire support system.

Researching the various foam machine technologies is a good idea in addition to considering specific manufacturers. For instance, differing materials or manufacturing processes used by particular manufacturers to create their foam machines may affect the consistency and quality of the foam generated.

Conclusion

A crucial choice that will affect your business for years is selecting the best foam machine for your requirements. You may make an informed choice to assure the success of your foam production by considering elements like size, capacity, foam quality, usability, pricing, and manufacturer reputation. Please do your homework and take the time to learn about the various varieties of foam machines available and their individual characteristics. This will make selecting the ideal machine for your requirements. Or you can contact us for a worry-free process.