Creativity is aware of no bounds, and inside the realm of creative expression, the equipment we use plays a pivotal function. One such device that has been revolutionising the creative panorama is the circular cutting machine. This humble but effective tool has the capability to free up new dimensions to your creative endeavours. Before we delve into the innovative possibilities, let’s understand what circular slicing machines are.

Understanding Circular Cutting Machines

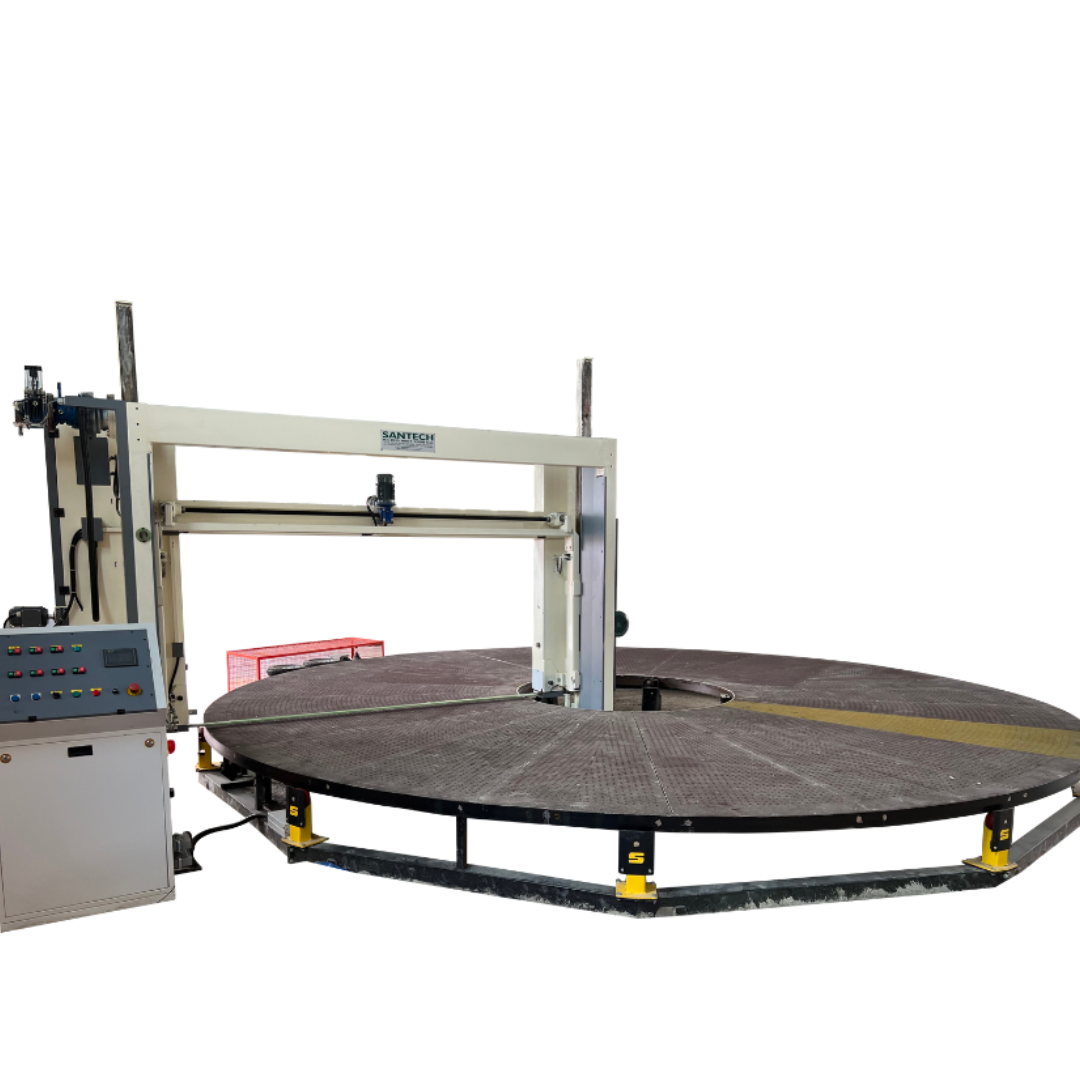

Santech Industries brings out a revolutionary machine that makes foam cutting precise and easy and increases optimum output. Equipped with a large circular platform, these foam cutting machines have an AC motor that moves the platform at the preferred speed, making it easy to cut the foam blocks continuously. With a precise thickness, this foam cutter is highly optimised to create precise foam sheets or mattresses.

Now, let us move forward and learn about the different ways in which you can unlock your creativity using these foam cutting machines.

1. Unleashing The Potential Of Circular Cutting Machine

Imagine a tool that successfully transforms a PU foam block into complicated, precisely reduced shapes. That’s the magic of these foam cutting machines. These cutting machines aren’t just about cutting; they are approximately liberating your creativity.

- Precision at your fingertips

The precision provided by foam circular slicing machines is remarkable. From delicate curves to complicated patterns, these machines will let you execute your imagination and prescience with accuracy. No greater suffering with manual cutting tools that restrict your designs – embody the finesse of a circular cutting device.

- Versatility in design

Whether you are crafting custom upholstery, designing thematic decorations, or developing prototypes on your initiatives, the versatility of circular cutting machines knows no bounds. It’s a game-changer for foam manufacturers who crave a variety of designs, presenting the ability to test with numerous sizes and style effects.

2. Maximising Efficiency

Efficiency is the cornerstone of any innovative procedure, and circular cutting machines excel in this aspect. The speed and accuracy with which our machines function are no longer time-consuming but also open up the possibility of tackling more challenging tasks. So, with Santech’s circular slicing machines, it is time to say goodbye to the boring hours spent on manual cutting and welcome a streamlined, efficient workflow.

- Seamless integration with technology

Modern foam circular slicing machines are designed to seamlessly combine with digital generation. In this approach, you can upload your designs immediately to the system, taking into consideration brief and particular execution. The union of traditional craftsmanship with contemporary technology is a game-changer for creatives trying to stay in advance within the virtual age.

- User-friendly interface

Don’t be intimidated by the advanced functions – our machines are designed with simplicity in mind. The consumer-friendly interface guarantees that even beginners can navigate the settings comfortably. It’s a device that empowers artists of all levels, promoting a creative environment in which all people can carry their ideas to existence.

3. Unlocking Your Artistic Potential

The adventure of unlocking your creativity begins with investing in the proper gear, and a foam circular cutting machine is a smart pick. Let’s delve into how this flexible system can elevate your artistic hobbies.

- Unleash your imagination

Gone are the days of being deprived by the restrictions of manual equipment. With a circular cutting system, your imagination takes centre level. Whether you are envisioning complex geometric patterns or whimsical shapes, this tool empowers you to explore the ways reaches of your creativity.

- Effortless prototyping

For creators concerned with prototyping and model-making, circular slicing machines are a blessing. These machines quickly translate your thoughts into real prototypes with precision and pace. It’s a vital asset for innovators trying to repeat and refine their designs efficiently.

- Crafting custom decor

Elevate your home decor tasks with custom-designed foam factors. Circular cutting machines will let you upload a private contact for your residing areas, creating specific pieces that reflect your style. With custom-designed cushions, your opportunities are constrained handiest via your imagination.

Let us now study a few upkeep recommendations for foam-cutting machines to ensure their longevity.

Maintainance Tips For Foam Cutting Machine

Maintaining a foam-cutting machine is important to ensure its toughness, efficiency, and safety. Here are a few maintenance guidelines for a foam cutting machine:

- Regular Cleaning: Clean your cutting machine regularly to remove dirt, debris, and accumulated foam residue.

- Machine Lubrication: Go through the manufacturer’s guidelines when lubricating your machine’s moving parts. This includes bearings, guide rails, and other things that ought to be lubricated to lessen friction and save your machine from getting damaged.

- Inspect And Replace Cutting Blades: Regularly investigate the cutting blades for signs and symptoms of wear, harm, or dullness. Replace blades as these had to hold the machine’s cutting precision and performance.

- Check Electrical Components: Inspect the electric components of the machine, including wiring, switches, and connectors, for any symptoms of damage, harm, or loose connections.

A Key Takeaway

In the ever-evolving landscape of artistic expression, a foam circular cutting device emerges as a beacon of innovation. Its ability to seamlessly blend precision, performance, and versatility makes it a crucial tool for creators throughout diverse disciplines. So, why wait? Dive into the world of countless creativity, where your thoughts come to existence with the precision and efficiency of a foam circular cutting machine. Unleash the artist in you, redefine your craft, and permit your imagination to leap to new heights.