Have you ever found yourself intrigued by the mesmerising process that transforms bulky foam into precisely shredded pieces? Behind this enchanting feat lies the realm of foam shredders – sophisticated machines that direct the reduction of foam into manageable fragments. In this exploration, we will delve into the intricate workings of foam shredder machines, unveiling the magic behind their operation and understanding the crucial considerations for choosing the right one.

What Is A Foam Shredder Machine?

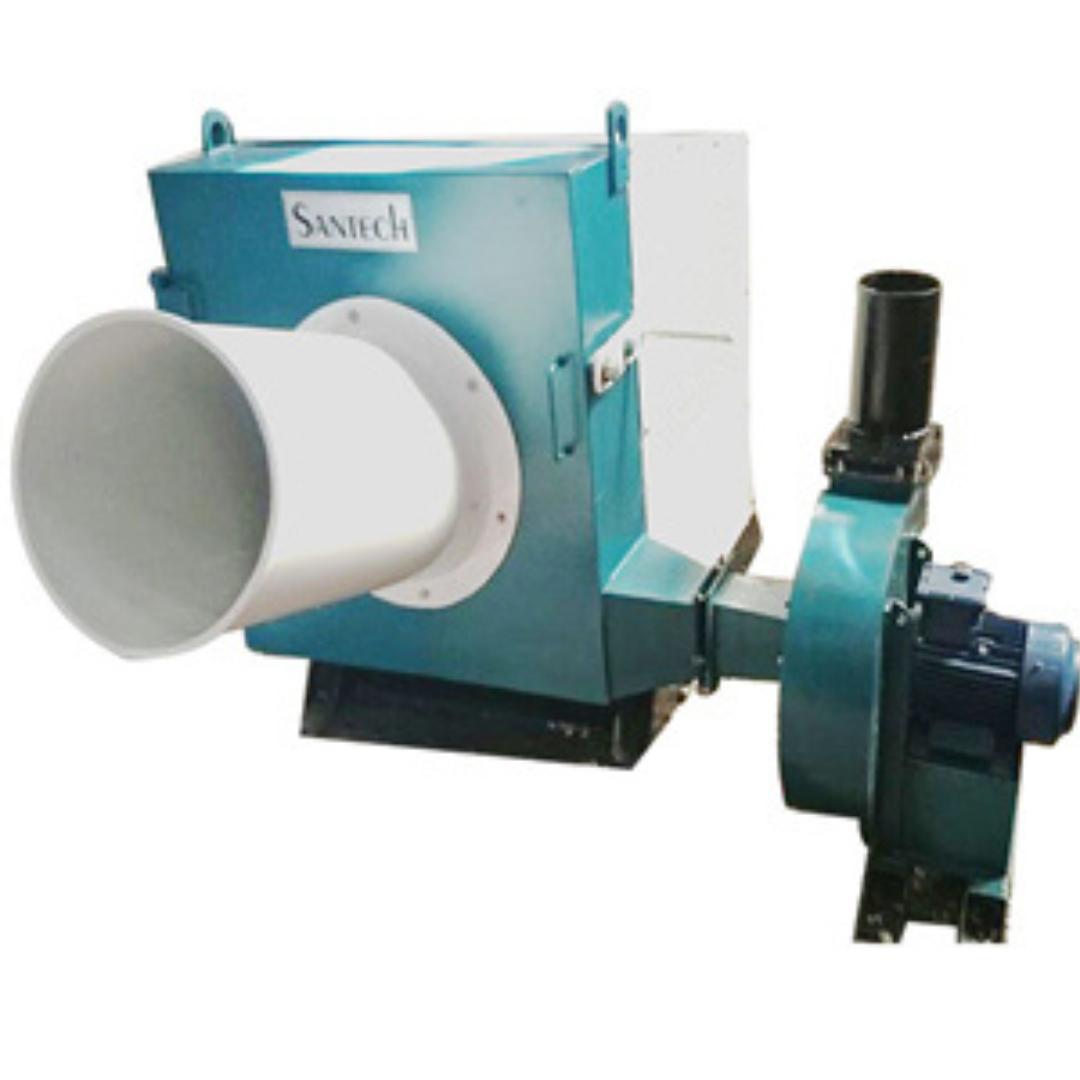

A foam shredder machine is a sophisticated piece of engineering designed to break down foam into smaller, manageable pieces. Its systematic operation involves sharp blades strategically positioned to efficiently slice through the foam. This process, complemented by sharp metal corners, ensures precision in cutting, resulting in uniformly shredded fragments.

Working Of Foam Shredding Machine

The symphony of sharp blades within the foam shredding machine transforms the seemingly unwieldy foam into precisely shredded pieces. As foam is fed into the machine, it undergoes meticulous cutting, producing smaller, more uniform fragments. The integration of sharp metal corners enhances precision, contributing to a consistent output suitable for various applications.

-

Understanding The Structure And Principle

Much like a shredder for paper, the foam shredder machine relies on a robust structure and a clear working principle. The inner workings involve a combination of blades and cutting mechanisms, creating a systematic approach to foam reduction. But how does this structure contribute to the overall efficiency of the machine?

-

The Role Of Sharp Metal Corners

One key element of the foam shredder machine’s structure is the presence of sharp metal corners. These corners, in conjunction with the cutting blades, ensure precision in the shredding process. The foam is not merely torn apart; it is meticulously cut into smaller fragments, maintaining a level of consistency crucial for various applications.

How To Choose The Right Foam Shredding Machine?

Selecting the ideal foam shredding machine demands careful consideration of several key factors:

- Capacity: Evaluate the volume of foam your operation requires processing. Choose a machine with a capacity that matches your workload, ensuring that it can efficiently handle the quantity of foam materials you need to shred.

- Blade Design: Scrutinise the blade design of the shredder. Different foam types may demand specific blade configurations. Opt for a machine with blades tailored to the characteristics of your foam materials to achieve optimal results.

- Maintenance Requirements: Assess the ease of maintenance. A machine with accessible parts for routine maintenance not only ensures longevity but also contributes to consistent performance over time. Regular upkeep becomes a seamless part of your operational routine.

- Power Consumption: Consider the energy efficiency of the machine. Opt for a foam shredder with minimal power consumption. This not only translates to cost savings in the long run but also aligns with environmental sustainability goals, making your operation more eco-friendly.

- Safety Features: Prioritise machines equipped with safety features. Look for mechanisms that prevent accidents during operation, ensuring a secure shredding process for users. Safety is paramount, especially in industrial settings where these machines are commonly used.

Benefits Of Foam Shredding

Beyond the immediate reduction in material size, foam shredding unfolds a spectrum of advantages that resonate across industries. Let’s explore these benefits, each adding a unique note to the symphony of advantages that foam shredding brings to the table.

-

Recycling Contribution

Foam shredding plays a pivotal role in recycling efforts. By breaking down foam materials, it facilitates their reuse across various applications, contributing to a more sustainable and environmentally friendly approach.

-

Customisation For Special Needs

Shredded foam finds applications in creating customised products, particularly for individuals with special needs. This not only expands the possibilities in design but also aligns with inclusivity goals in manufacturing processes.

-

Space Optimisation

Beyond the apparent reduction in size, foam shredding optimises storage space. This is particularly valuable in industries dealing with substantial quantities of foam materials, enhancing overall efficiency and organisation within the workspace.

-

Environmental Impact

Foam shredding aligns with broader environmental goals. By promoting the reuse of materials and reducing waste, it fosters a more sustainable approach to manufacturing processes, contributing positively to your ecological footprint.

-

Cost Savings

Beyond its environmental merits, foam shredding can lead to significant cost savings. By breaking down foam into smaller, more manageable pieces, businesses can optimise material usage. This efficiency not only reduces the need for excess raw materials but also streamlines production processes, ultimately contributing to a more economical and resource-efficient operation.

Summing Up

The foam shredder machine transcends its role as a mere size-reducing device. It stands as a sophisticated solution with far-reaching benefits. Understanding the meticulous working mechanisms, making informed choices in machine selection, and recognising the broader advantages of foam shredding collectively contribute to a more informed and sustainable approach to material processing. The next time you encounter a foam shredder, take a moment to appreciate the science and innovation that make it an integral part of modern manufacturing and recycling processes.