Have you ever thought about what goes into the comfortable core of your mattress? The answer lies in a fascinating world of industrial machinery and cutting-edge technology. The world of the foam industry relies on a surprising tool: the foam machines. But unlike the machines that create the bubbly layer of your cappuccino, these aren’t for creating culinary delights.

In this blog post, we will guide you about the benefits of investing in a high-quality foam-making machine, which is used in packaging, furniture, automobile, footwear, construction, sanitaryware, and many more sectors. This blog will help you make the right decisions when buying, operating, or renting a foam machine for yourself.

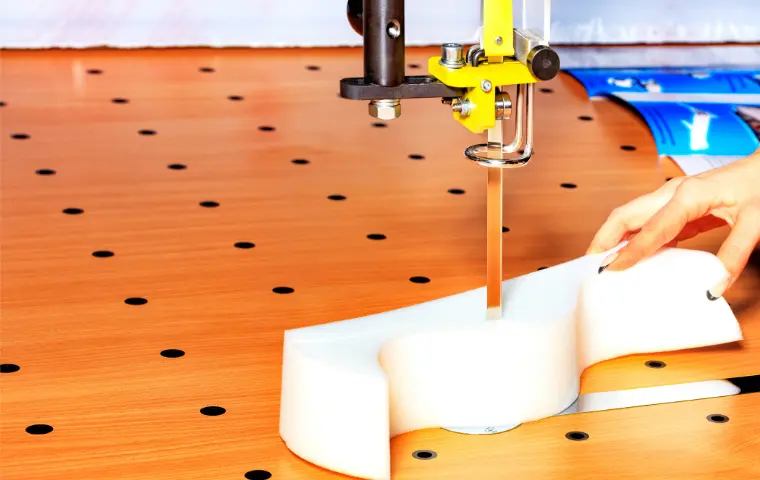

What Is A Foam-Making Machine?

A foaming machine is a specialised industrial device designed to generate and control foam with precise properties. It achieves this by introducing gas under pressure into liquid solutions. Often, a foaming solution is also incorporated to enhance the stability and achieve the desired foam characteristics.

From creating new materials to enhancing existing products, foam machines play a significant role in our world. Compared to manual methods, these machines offer precise control over various factors. This allows for:

- Consistent and repeatable foam generation for industrial and research purposes.

- Tailoring the foam properties for specific applications.

Understanding The Need To Invest In Foam-Making Machines

The protective packaging of your delicate item, the comfort of your mattress, and even the efficiency of your home insulations have one thing in common: foam. Now you might wonder, why invest in such a machine? Here are some points for better understanding the need to invest in foaming machines.

-

Quantifiable Benefits

Manual foam creation takes a lot of time, but these high-quality machines produce foam within mere seconds. There is at least a 50% reduction in costs and time for foam preparation, which shows how these machines can lead to higher profits.

-

Environmental Impact

Traditional, manual foam creation methods often leave a trail of wasted resources and environmental concerns. Here, foam-making machines emerge as game-changer reducing the amount of waste sent to landfills.

-

Future Proofing Technology

Foaming machines are adaptable to the ever-evolving needs of the foam industry. Their ability to create diverse and precisely controlled foams opens doors to various new applications such as advanced material development, cushioning innovation, and sustainable filtration systems.

7 Benefits of Investing In High-Quality Foam-Making Machines

Foam-making machines are very versatile pieces of machinery. For anyone who relies on precise and consistently controlled foam, investing in a high-quality foaming machine opens a world of benefits. Here are 7 reasons why you should invest in a high-quality foaming machine.

1. Unwavering Control Over Foam Properties

Foaming machines offer major control over key characteristics of the foam, unlike the manual method of bubbling or whipping. Precise control over density, bubble size, and distribution can significantly impact the performance of the foam.

These machines allow you to adjust these factors with precision, ensuring:

-

Repeatable Results:

These machines keep the “foam configurations” the same every time, so you know your foam blocks will be perfect. Consistent foam means consistent results, letting you focus on what matters most.

-

Tailored Foam For Specific Applications

Industrial application often requires foam with specific characters. For example, packaging needs foam with a particular density to protect the delicate items during shipping. These foaming machines allow manufacturers to tailor foam properties for optimal performance according to their specific use.

2. Boost In Efficiency

These foaming machines offer significant time savings by automating the process, generating consistent foam rapidly within seconds. This is a very big deal in busy manufacturing facilities where workers can use that time for more important things, and in factories as well where faster production means more foam products get made.

3. Scalability

The scalability of foam-making machines can be adjusted to make foam according to the customer’s need. This comes very handy in factories which start small and grow bigger, just like a seedling turning into a tree.

4. Enhanced Material Properties

These machines can handle special foam formulations such as superior strength, reduced weight, or better protection against heat. You can also adjust the size, shape, and amount of foam to create composites with specific properties.

5. Innovation And Exploration

By making different types of foam, you can explore innovative ideas! They can create special filters to clean dirty water or polluted air, or even come up with something we can’t even imagine yet!

6. Consistent Quality

These high-quality machines make sure the foam you make is always the same. Precisely monitored foam machines can improve the properties of various foams. It’s not just about creating bubbles but unlocking new possibilities. The ability to create diverse foam types opens doors to exciting research and development endeavours.

7. Reliability And Durability Of Foam-Making Machines

These machines are very durable and can handle being used a lot, so they won’t break easily. This saves a lot of time on repairs and keeps your foam production running smoothly, without any unexpected stops.

Conclusion

In conclusion, foam-making machines are more than just bubble generators. They unlock several possibilities in research, development, and various industries. They open doors to new applications across various fields, offer precise command over foam properties, and significantly improve efficiency. These machines play a very important role in creating the specific types of foam needed for countless applications in the world.

Santech Foam Machines is the leading manufacturer and supplier of foaming and foam-cutting machines, guided by quality orientation. The products manufactured by Santech Foam Machines are of very high quality. We have more than 25 years of experience in this industry making them the best in the market. We ensure timely delivery of their product and also provide personalised after-sales services and support. With the aim of continuous improvement and setting milestones in the line of client satisfaction, we constantly innovate and develop new technologies to meet evolving foam business needs.