Polyurethane foam is a material that is commonly utilised in many industrial fields because of its excellent heat insulation capabilities. Due to its flexibility, PU foam may be moulded into various unique shapes, expanding its use in commercial and consumer goods. While rigid PU foam is extensively employed in commercial or residential structures in the form of roof and wall insulants, as well as air barrier sealants, flexible PU foam is mainly used as cushioning in beds, mattresses, furniture, packaging, and vehicle interiors. Due to the extensive range of uses and applications for PU foams, the foam cutting machine sector has seen significant technological breakthroughs.

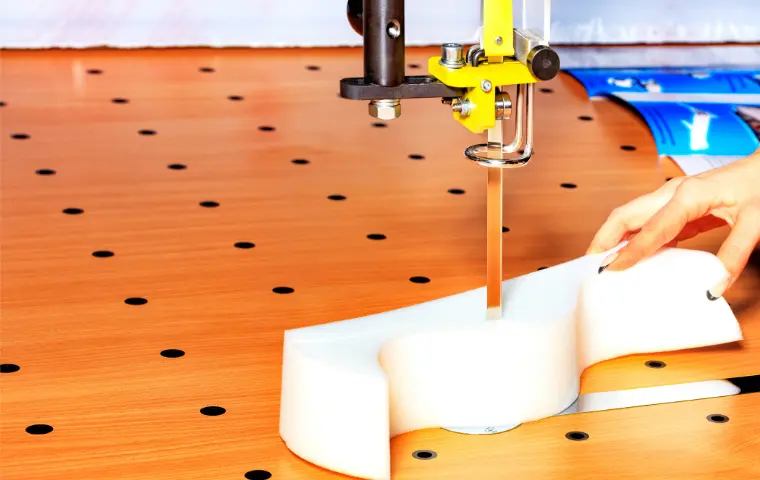

High-density foam can be cut with the help of a foam cutting machine into various intricate forms, slices, blocks, and sheets. The foam cutting machines come in multiple sizes and shapes and can be fully or partially automatic. In this way, a foam cutting machine is often a substantial investment because it facilitates product design and promotes business growth. However, you must know the cutting tool that best meets your requirements. The thickness of the foam and the product you want to create with it are the two most significant factors to consider when selecting your foam cutting machine.

Circular Foam Cutting Machines And Their Uses

Circular foam cutting machines are designed to accurately and diligently cut foam of different densities. The configuration of circular foam cutting machines consists of a fixed cutting section and a circular table top that rotates thanks to an AC motor that a PLC operates. When the device is turned on, the table moves in a circular motion, cutting the PU foam blocks to the required size and thickness. Machines for cutting circular foam are made to handle high production unit yields. Like any PU foam cutting machine, circular foam cutting machines efficiently obtain foam blocks of desired dimensions and shapes. These blocks are further used for cushioning in upholstered furniture and automobile industries.

Vertical Foam Cutting Machines And Their Uses

In the foam industries, vertical foam cutting machines are used to cut big foam blocks into the necessary shapes, sizes, and slices. Vertical cutting machines provide a reliable and adaptable way to cut PU foam. The usage of vertical foam cutting equipment is advised for pruning the polyurethane block slides. The amount of space used by the machine system differs depending on the model and size of the machine. An electrically controlled blade motor and an adjustable side support system make up a vertical cutting machine. The aluminium table top on which the PU blocks are set allows for the free movement of the PU blocks.

Additionally, the machine’s slitting segment has four balanced blade wheels and a hand brake to quickly stop the movement of the tabletop. The equipment also has a motorised grinding attachment and two-way band knife guiding. Signage, solid architectural modelling, props, prototyping, and making moulds for concrete and plaster casting all use vertical cutting machines.

Conclusion

To accommodate the many requirements of our client’s production plant, Santech Industries provides a wide variety of circular and vertical PU foam cutting machines. We have a cutting-edge production facility with the newest equipment built with advanced German technology to produce machines for customers’ needs. To enquire more, contact us now!