A horizontal foam cutting machine also referred to as a foam cutting machine, is a potent device utilised in many different industries, including the production of foam goods like foam cushions, foam mattresses, and foam padding. These devices are commonly employed in producing numerous foam items and are created to cut huge blocks of foam into smaller, easier-to-handle pieces. Examining the significant risks associated with this equipment’s functioning to establish a safe working environment is essential.

Leading foaming machine manufacturers, like Santech Foam Machines, strongly emphasise safety when operating their products and offer detailed safety instructions to guarantee that their products are handled as safely as possible. The significance of safety when using a horizontal cutting machine will be covered in this article, along with the essential safety measures that need to be implemented.

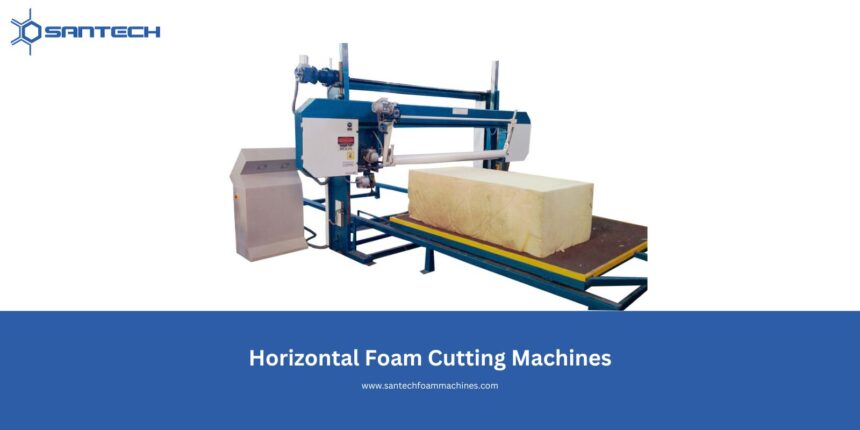

Understanding The Horizontal Cutting Machine

It’s critical to comprehend how a horizontal cutting machine operates before discussing the safety measures related to using one. Large, commercial-grade saw blades installed on a horizontal axis make up a horizontal cutting machine. A robust motor drives the saw blade with a fast rotational speed. The cutting table is covered with the foam block, and the saw blade is dropped upon it. The blade makes a smooth, accurate cut as it slices through the foam. The machine can be modified to cut at various depths to produce foam products of varied thicknesses.

Safety Precautions While Operating Horizontal Cutting Machine

Although horizontal cutting machines are practical tools, several risks must be considered when using them. Some of the most crucial safety considerations to remember when using a horizontal cutting machine include the ones listed below:

Always Wear Protective Gear

When operating a horizontal cutting machine, it is imperative to put on safety equipment, such as gloves, earplugs, and safety glasses. Protecting your eyes and hearing from the saw blade’s potential for producing a lot of dust and debris is crucial. It is vital to wear a mask since the dust and waste created by the cutting process can lead to respiratory problems if inhaled.

Keep Your Work Area Clean

Always keep your workspace tidy and clutter-free. A disorganised workspace might raise accident and injury risks. The foam may also move due to the debris on the cutting table, making the cuts less accurate and raising the possibility of damage.

Use The Machine Only For Its Intended Purpose

Never utilise a horizontal cutting device for a task other than what it was designed for. The possibility of accidents and injuries can rise as a result. The machine may become damaged and less effective if it is used for jobs for which it was not intended. Following the manufacturer’s equipment operation and maintenance instructions is also essential because straying from them might lead to more accidents and injuries.

Be Aware Of The Saw Blade

Always be mindful of where the saw blade is. While the blade is cutting, avoid reaching into the vicinity. If an object or body part comes into contact with the saw blade while rotating at high speeds, it could seriously injure the victim. Protecting other people and animals from the cutting area is crucial to prevent mishaps.

Keep Your Hands Away From The Blade

Never put your hands near the blade. Your hands risk suffering severe injuries if they come into touch with the knife. It’s crucial to handle the foam with tools and equipment rather than your hands and to adjust the cutting table.

Follow The Manufacturer’s Safety Guidelines

When using the machine, adhere to the manufacturer’s safety instructions. Important information on how to operate the equipment safely, as well as how to maintain and repair it, may be found in the manufacturer’s instructions. They also contain details on how to use and care for various parts of the equipment, such as the saw blade.

Regularly Check And Maintain The Machine

Regular inspections and maintenance ensure the machine is in good operating order. Any worn or broken parts should be inspected, and any repairs should be made immediately. By doing so, you can ensure that the machine is running as safely and effectively as possible and reduce the risk of mishaps and injuries.

Have A Proper Training

Before utilising a machine, it is crucial to have the appropriate instruction on its safe use and functioning. This can guarantee that the equipment is being operated safely and correctly and reduce the risk of accidents and injuries.

The Crux

One must exercise extreme caution and pay close attention to safety procedures when operating a horizontal or another foam-cutting machine. These machines are effective equipment that may be used to make various foam products, but if not utilised properly, they also carry a high risk of serious injury. Operators can reduce the hazards associated with these machines and guarantee a safe and effective working environment by adhering to the safety recommendations of leading foam machine manufacturers like Santech Foam Machines and being aware of the critical considerations discussed in this article. A tidy and secure workplace raises the finished product’s calibre and protects the operator from harm. It’s crucial to pick a respected manufacturer who can offer various options and assist in designing a practical and ergonomic plan.